04/09/2020

Construction sites need scaffolding, this goes without a question. Painters, plasterers, window fitters, roofers and many other trades need scaffolding in order to carry out their work on facades, window installations or roofs effectively. Scaffolders aim to be seen as a useful support to construction workers rather than a disruptive factor.

|

This is why ‘We bring you up safely’ is the slogan of the scaffolding company Kolb GmbH. Stefano Battaglia took over the traditional scaffolding company with 2 employees in 2010 and today employs a team of 30 who work within a radius of 150 km around the location of Rimbach in Odenwald, Germany. The company is characterised by providing detailed consultations as well as speed of delivery and competence in their field of work. Safety and compliance with rules and regulation are, one of their top priorities. |

The company’s usual workflow is as follows: Initially, there is consultation with the customer, followed by providing a detailed quote. This then, hopefully, is followed by getting the job and subsequently scheduling work for fitting and later on dismantling the scaffolding.

The daily tasks of Mr. Battaglia centre around customer contact and finalising quotes for the work.

Every first contact is recorded in the office, followed by the quotation phase. This means that Mr. Battaglia or his site manager drive to each construction site in person. Customer data, photos, information from Google Earth or even measurements from a competitor's quote are not accepted because measurement data needs to be accurate and up to date.

|

They used to visit construction sites with a measuring tape and a Leica DISTO laser distance meter. In addition, smart phone pictures were used to have a visual record and subsequently provide knowledge about which measurements belong where. This was followed by manually sketching a floor plan and adding lengths, heights, potential bays, gables, or roof overhangs. |

Many of these areas are often hard to access or difficult to measure which frequently resulted in guessing the distance rather than measuring. This manual process took a lot of time, often between 30 and 45 minutes to gather all the needed measurements for a quote. Meaning, a total of around 6 construction sites could be visited per day.

Using the BLK3D, only 4 minutes are needed on site to gather all the required measurement data – meaning that up to 17 sites can be visited each day. This is an immense increase in efficiency. Even more sites could be visited, however, traffic in the Rhine-Main area is usually heavy, resulting in travel times of around 30 minutes for each 20 kilometres.

We try to keep the contact with customers on site as short as possible, as the conversation usually takes longer than the time we need on site with the BLK3D,

says Mr Battaglia with a smile.

The detailed workflow with the BLK3D is as follows: Position yourself close to the entrance of the building and take the first picture, then continue this process clockwise and take a picture of each side of the house. If a house is too wide, it is usually divided into two sections or more.

When you provide around 1,200 quotes to potential customers per year, the process has to be as efficient as possible. This means that during a site visit only 3D Images are taken – no measurements are created on site. The technician in the office then connects the BLK3D to a computer and downloads the images. All measurements needed for the quote are then created with the BLK3D Desktop software. The technician knows exactly which measurements are needed to determine the square footage for the quote. This streamlined process allows for next day quotes and images with measurements attached for the customer’s reference.

Clear advantages for scaffolders using the BLK3D are:

- Project documentation with measurable images

- Measurements are digital and everyone can read them – no more errors due to illegible handwriting.

- The pressure of running a scaffolding business is high, the phone always rings. However, using the BLK3D ensures that even during busy times measurements aren’t missed and it avoids any transcribing errors.

- The acceptance of a quote can, in some cases, take longer than a year. The BLK3D allows you to open your files at any later point in time to check or create additional in-picture measurements. This is particularly useful when a customer’s initial request changes - which can happen around 5 times per week. For example, after consideration, a customer might up their budget and they now not only would like to redevelop their façade but also the roof or even add a balcony to the house. Previously, this meant re-visiting the construction site but with the BLK3D all needed data is available and the additional measurements can be created right away. This is much more efficient as an additional site visit isn’t needed. Plus, the added benefit for the customer is that no additional costs arise due to a change request.

The pictures with measurements are handed to employees and used during the installation. This has the great advantage that they already have all measurements they need. They still use a DISTO laser distance meter to double check but variations between this and the in-picture measurements are usually less than one centimeter. If the process is followed correctly, meaning two images are taken which are then overlaid, the accuracies are more than satisfactory for a scaffolder. For the final invoice, however, measurements of the actual installations are used.

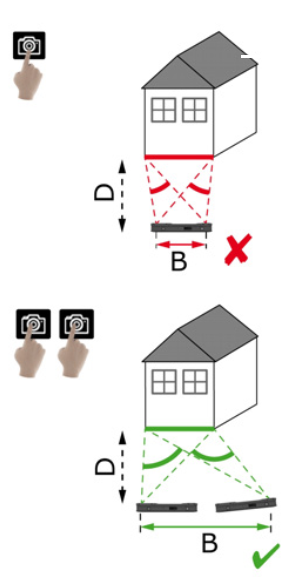

The BLK3D Imager has a calibrated stereo camera which simultaneously captures two images of the same scene from two different perspectives at the same time. This is similar to the human three-dimensional stereo vision which our left and right eye provide to us. To achieve a very high accuracy, Leica Geosystems recommends the Multi-Shot; meaning four images are overlaid and the accuracy is increased. The distance to the facade should be as low as possible.

The scaffolding company Kolb put the BLK3D to the test and measured a rather complicated construction site, once with a DISTO laser distance meter and once with the BLK3D. It took one hour and 15 minutes with the laser distance meter but the BLK3D completed the same task in only 8 minutes. This increases the efficiency more than ten-fold.

Stefano Battaglia says about himself that he isn’t very computer-literate, but in his words the BLK3D Software is ‘fool-proof’ to use. He ‘only’ takes the images but even the technician figured out everything he needs to know on the BLK3D Desktop Software in less than 2 hours.

In the construction industry you need technology which is easy to understand and use. Few tools and little add-ons are required, and this is what the BLK3D is about.

says Stefano Battaglia.

His involvement in the scaffolding industry goes beyond his own company. For example, Mr. Battaglia is the regional representation for the scaffolding guild in the state of Hesse and he also holds a permanent position in vocational training committee. He is seen as an ‘innovator’ in his trade which has led to 22 of his colleagues now also using the BLK3D. He is convinced that the BLK3D will gain momentum in this market.