04/01/2020

The main challenge when taking on a renovation project of this size is aligning and installing all windows horizontally with absolute precision. Macun Innenausbau GmbH is well-known in Switzerland for 10+ years for the professional handling of complex projects in the areas of window, door, kitchen and sun protection installation, as well as for the compliance with quality, deadline and cost requirements. All fifty-eight full-time employed fitters are fully equipped with tools and vehicles to provide a consistent high level of quality. With regard to this specific project, the dismantling and installation of the windows was assigned to the company. A total of approximately 650 square metres of windows were dismantled and reassembled - plus all finishing work such as grouting, cementing and attaching cover strips was completed.

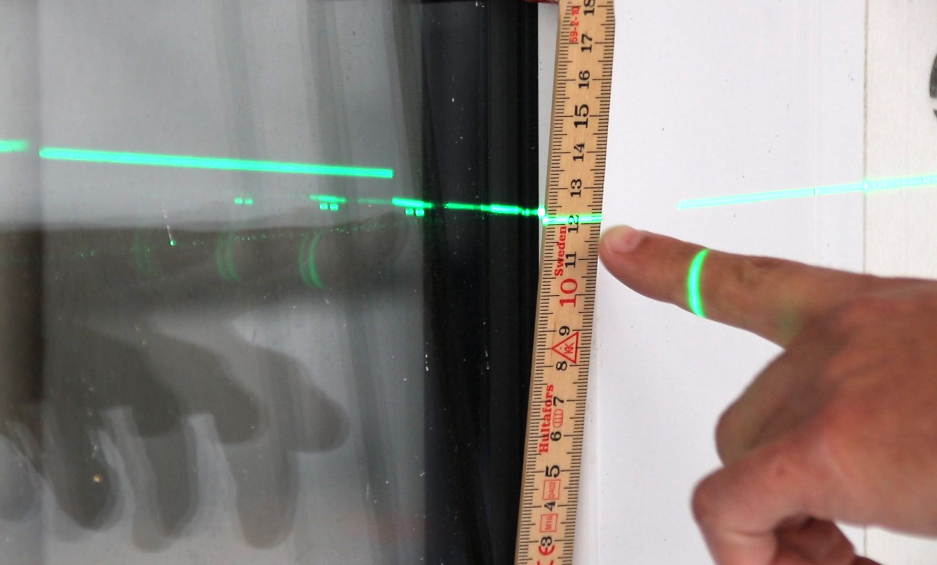

Most commonly window fitters measure by attaching a line laser to soffits (ceilling) in a room. This reference measuerement then allows for the horizontal alignment and installation of windows with the help of window packers.

The facade length of this specific office complex is about 30 meters and, therefore, the installation of the windows at the same height is of utmost importance to give the building a uniform look and feel. The line laser provides the reference height and window packers are then used to raise or lower the height of each window to have them all at the same height.

The window fitters were very satisfied with the magnetic twist adapter of Leica Lino L2P5G. Space limitations in this building didn’t allow for a tripod setup, but the magnetic adapter of the L2P5G allowed for easy attachment to a metal frame.

The operation of the laser is also very simple, as it covers all possible functions with a single button.

Li-ion battery technology adds to the user-friendliness of the device. It enables the laser to be used for more than two working days on a single charge.

My mechanics (fitters) agree that using the green laser results in a significant timesaving,

highlights Jonas Tschurtschenthaler.

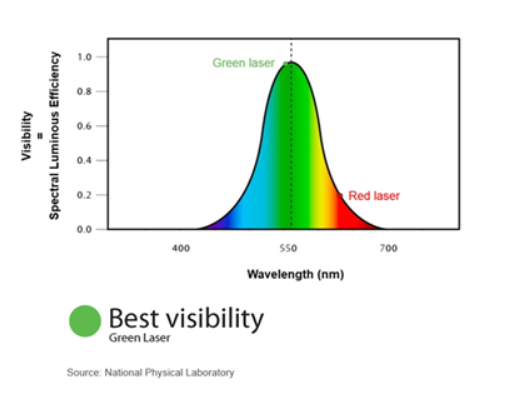

The visibility of the green Lino laser beam is very good. They used to work with red line lasers, but the red laser beam was hardly visible in bright lighting conditions or when working outdoors, which is usually the case when it comes to window installations.

The Leica Lino L2P5G uses green line and point lasers. This increases the laser visibility in bright environments and large spaces. This is due to the fact that green light is better visible to the human eye, compared to red light.

|

Why are green lasers between four to six times more visible if compared to red ones? Having a look at the chart below, it becomes clear that the latest Lino red lasers reach about 0.2 Spectral Efficiency/Visibility. The new green Lino lasers have up to 0.9 Spectral Efficiency/Visibility, meaning they are already four times more visible to the human eye. Plus, the LP25G has approximately 50% more laser power if compared to standard DIY line lasers in the market which further increases visibility. In addition to all these features, all Lino devices operate with laser class 2 and don’t require any specific knowledge or training. |

In summary, the advantages of the Leica Lino for a window fitter are the high visibility of the laser beam, the long battery life and the ease of use,

says Jonas Tschurtschenthaler as a closing remark of his interview.

Jonas Tschurtschenthaler

Project Manager at Macun Innenausbau GmbH, St. Gallen, Switzerland