Health facilities that effectively treat and heal people who walk through their doors are vital for society. When these facilities function well, patients are properly cared for, healthcare staff does their best work, and medical advancements create better healthcare outcomes. To keep this cycle of medical progress continuing, form must always follow function, designing hospitals and health centers that always seek to treat, comfort, and heal. With design specializing in healthcare consulting, restoration, remodeling, lab design strategies, and biophilic design, HOK is a design, architecture, engineering, and planning firm established in 1955 that dedicates itself to “designing spaces that support and promote health, wellness, and equitable access.”

Recently we spoke with Eric Bogenschutz, Sr. Design Technology Manager at HOK, about his process with the Leica BLK2GO. Eric traveled to Tulsa, Oklahoma, on a few occasions to document facilities and spaces with 3D laser scanners and reality capture technology. His first trip to Tulsa was to scan Saint Francis Hospital in preparations for upcoming renovations. HOK is renovating the health center’s first floor and expanding its square footage with new additions.

For this project, Eric noted that the HOK team “needed a way to gather pre-existing conditions that were accurate and in a quick manner. So, we chose the BLK2GO for the bulk of our assignment.”

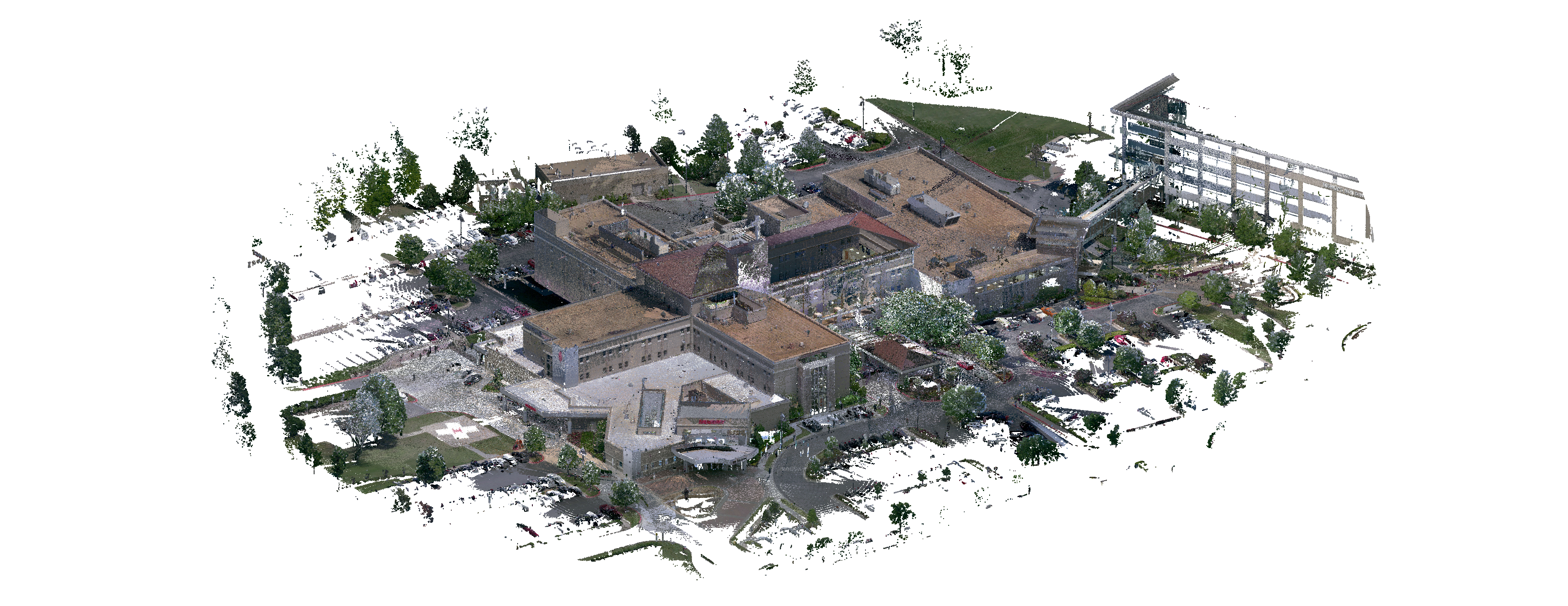

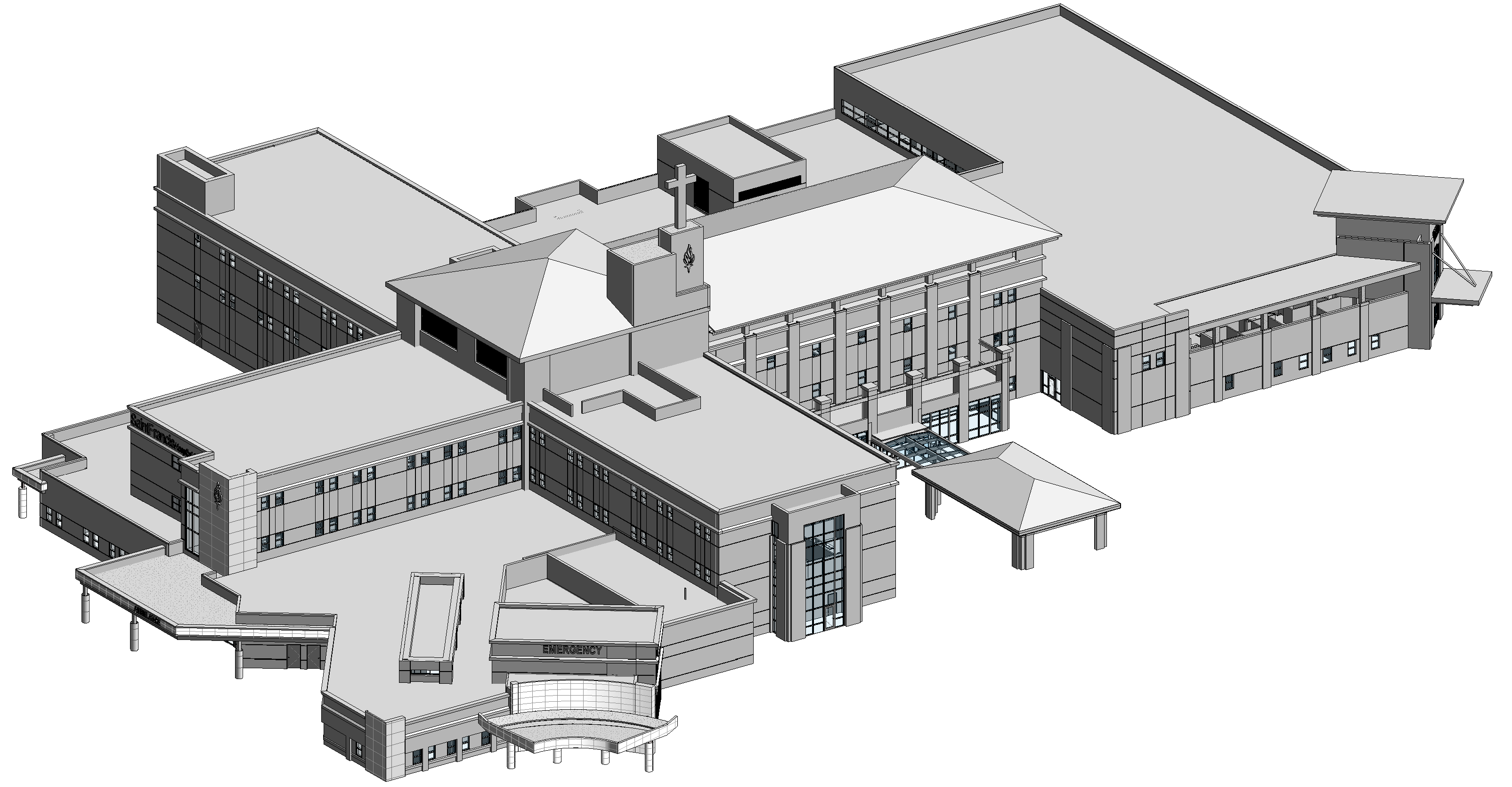

Documenting existing conditions is one of the first steps in renovation crucial to HOK’s work in redesigning spaces; they need accurate measurements as their design base. This design base, or “existing conditions model,” serves as the foundation for new construction, new design, and the creation of demo plans. The scope of the hospital is a large 200,000+ sq ft. [18,580 sq. meters] floor plate, with each room on the 1st floor scanned along with corridors and stairwells. To speed up the process with such a massive, active hospital, Eric scanned with the BLK2GO.

Documenting existing conditions is one of the first steps in renovation crucial to HOK’s work in redesigning spaces; they need accurate measurements as their design base. This design base, or “existing conditions model,” serves as the foundation for new construction, new design, and the creation of demo plans. The scope of the hospital is a large 200,000+ sq ft. [18,580 sq. meters] floor plate, with each room on the 1st floor scanned along with corridors and stairwells. To speed up the process with such a massive, active hospital, Eric scanned with the BLK2GO.

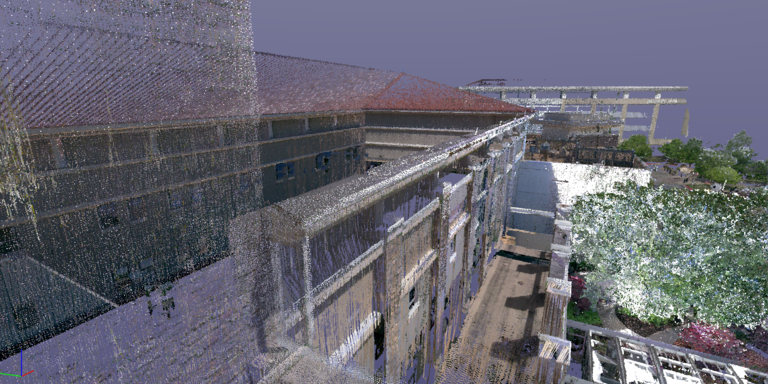

“All the interior scanning was accomplished in one long day, allowing our on-site team to focus on fighting raindrops for our exterior scanning scope of work,” Eric said. When compared with terrestrial laser scanners, he added that “using the BLK2GO, we can complete the same amount of work that we used to be able to complete in the past in a tenth of the amount of time.” That’s a productivity boost of over 90%!

Why? Well, there’s no set-up time: hold the BLK2GO, press the button, and walk through the desired space. As Eric puts it, “With no tripod to set up, that’s a big plus! Because when maneuvering through large spaces, it’s extremely helpful to have a portable mobile unit.” The mobile imaging laser scanner uses LiDAR and Leica Geosystems GrandSLAM technology to track itself through the space while a person walks, collecting all necessary data along the way. On the other hand, with terrestrial laser scanners, the scanner must be set up and positioned correctly for each individual scan, but there’s no waiting on the BLK2GO. Eric simply held it as he took his scan path through each room in the health center.

Saint Francis was a huge project to scan, yet the scope of the active health center was a job the BLK2GO handled well and sped through rapidly. A project that could’ve taken a couple of weeks was condensed into just one trip over a few days total.

The BLK2GO not only got the job done fast. It also was hassle-free.

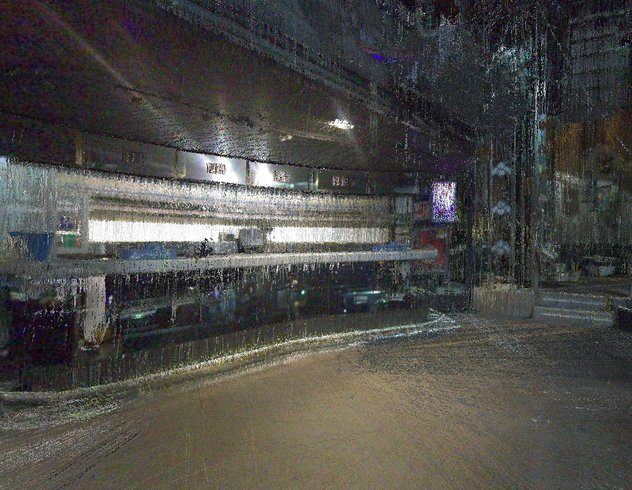

To walk into a patient’s room (with the approval of patient and nurse) for a total of 5 seconds scan and head out is a total game-changer.

With the BLK2GO in hand, Eric scanned patient’s rooms, emergency departments, and offices on Saint Francis’ first floor. Yet there was nothing to set up, no cables trailing after him or crew – just Eric with the BLK2GO in hand gliding from room to room. “That nimbleness of the BLK2GO was key to getting into spaces quickly and efficiently”, Eric notes, “and no one was opposed to somebody walking in their room to quickly scan, then turn around and leave in a matter of moments, trying to scan an active emergency room with a terrestrial scanner that has to stay stationary for a few minutes means a lot of rescans, with the BLK2GO there was no need to stop and rescan as a hospital bed rolled by. Patient care and safety along with hospital staff accessibility always comes first, not having a tripod placed in a corridor that restricts movement is a win-win in my book!”

And so the mobile scanner contributed to a quick visit – once the data was collected, Eric was into the next room. “All told, when you consider on-site savings and then registration savings – because you’re not registering individual scan locations – time spent on-site is significantly less than with terrestrial scanners.” With terrestrial scanners, individual scans from each static position must be registered, taking much more time to register and scan a space. But with the BLK2GO, registration time is reduced because it keeps scanning while you walk through large areas. "Our team registers the scans, transitioning our workflow into Register 360, then onto LGS and RCP, ultimately the team does their tracing work in Autodesk Revit, where the existing conditions model is created and serves as the base for construction documents for all designs concerning the project.”

Because of the BLK2GO’s speed and agility, Eric even scanned the roof areas that were accessible to him – “if I could get on the roof, I’d scan it,” he said. Eric’s job of capturing the existing conditions of Saint Francis’ ground level, stairways, and roof was made to be much speedier, efficient, and even a little more fun with the BLK2GO in hand. “As I walked into patient rooms and emergency departments—of course with permission from staff and consent from patients—I fielded curious looks and questions,” Eric recalls.

“When seeing the handheld scanner, some patients asked, ‘will that erase my memory?’” as they joked about the devices from the Men in Black film series. “The patients and I would laugh, but I assured them that the device in my hand was a mobile laser scanner – nothing else.”

For redesign and construction to run smoothly for any facility, accurate data must be collected. In all projects Eric took on in Tulsa, the BLK2GO was his tool of choice for its efficiency and speed. Eric and his team saw substantial productivity improvements from scanning active health sites like Saint Francis to scans of a local college and a 10,000 sq. ft. [930 sq. meters] mansion with the BLK2GO. The team significantly reduced their time spent scanning large spaces, and their workflow was made faster with reduced registration times for scans.

The team also saw a reduction in the equipment needed for projects. On Eric’s solo projects, the BLK2GO was all he needed. “I’d grab the BLK2GO, put it in my backpack – with no extra equipment needed and go scan. Because of the BLK2GO’s scanning speed, I had the time to scan twice just in case to assure our data was complete.”

HOK quickly provides the scans needed for their designs so teams can effectively start redesigns and construction. With the BLK2GO, HOK rapidly sped up projects, and Eric gained autonomy in his workflow when visiting current worksites. These efficiencies gained by HOK, specifically their work in healthcare facilities and hospitals, quickly get them into spaces to capture the data needed to continue their mission to “approach every aspect of a hospital building as an opportunity to boost staff health and wellness.”

“Are there scanners with greater density and highly accurate devices available? Yes, of course, but we’re not trying to document a heritage site, we’re capturing images and performing a “Field Survey” to share with our project teams who can use the data to virtually visit the building at any time, from anywhere in the world. As long as we understand the purpose behind what we’re scanning and how the data is going to be used downstream, we’re satisfied with the level of accuracy provided by the BLK2GO based on the benefits of speed and portability of the device,” Eric added.

“At HOK, we understand that our use of laser scanning isn’t intended to replace actual survey work, but is simply a starting point for our teams to replace an existing “Field Survey” workflow that traditionally would include sending multiple team members out to a site to take pictures and measurements only to realize that the process isn’t very accurate and usually an incomplete set of data is the end result. We’re not trying to supplant the use of other professional services, but to supplement their work with ours for a better overall and accurately documented project.”