01/01/2019

Schmid Metallbau was founded as a classic metal workshop in 1993 and today has a total of 15 employees. Their daily tasks focus on metal construction and design where high quality work and a high attention to detail is of utmost importance. To achieve this, thorough project preparation is essential.

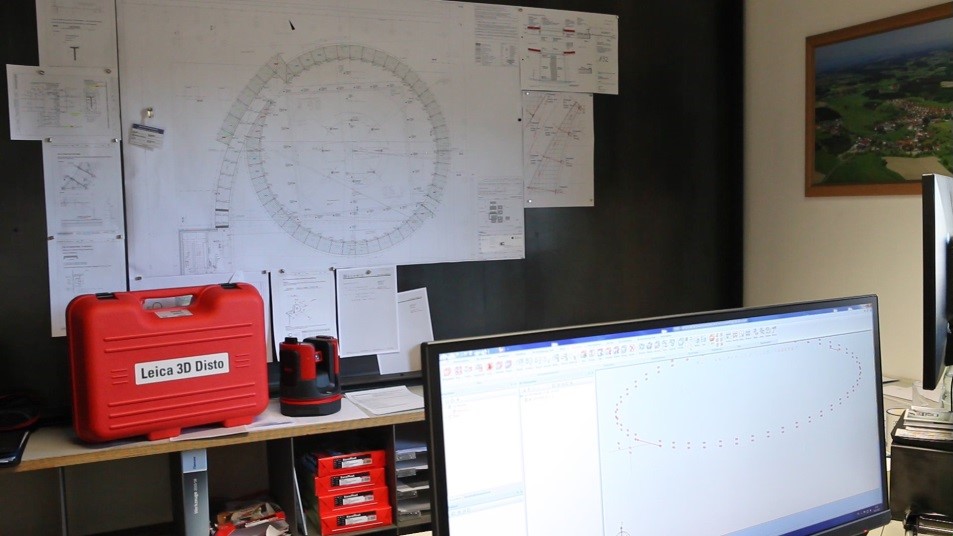

In spring 2017 they were given an exciting new project: the design and construction of an outward facing railing for a helipad on top of the roof of a newly-built hospital. The helipad’s built-in components to install the railing are positioned along the edge of the structure in a circular way. Unfortunately, the installation was not carried out with the required accuracy. The result is that all pre-installed components face different directions, twisted to the left or right and tilted in or out. Therefore, each individual holder was required to be measured and modelled individually.

2.5 m long cantilevers had to be fitted outward facing to the built-in components, onto which a platform is installed again. The railing running around the platform in a circular way is very labour-intensive to manufacture. Metal is bent with a special tool, so everything fits seamlessly when installed on site. A misfit would cause big problems.

It’s just like when you can’t close your belt anymore because you’ve gone past the widest hole

says Markus Schmid with a grin

In addition to the outward facing railing a steel net is installed. In a worst-case scenario this net must withstand catching a falling helicopter.

Schmid Metallbau took on the challenge and decided to visit the BAU exhibition in Munich with the goal of finding a solution to these complex, 3D measurement needs. They found the 3D Disto and then approached a colleague who already owned the product. After sharing his experiences and giving a more detailed explanation of the product, they were convinced and ordered the 3D Disto right away.

Markus Schmid then discussed with both his foremen which other supporting tools they could utilize. They designed a simple target plate which they could mount to the tilted, pre-installed, outward facing components. The 3D Disto was set up in the centre of the helipad so it could record all 54 structural components at once. After only re-positioning the 3D Disto twice in line with the 3-point-method, all measurements were completed quickly.

Using conventional methods, such as a tape measure or a laser distance metre, would not have made it possible to complete these measurements.

As the person responsible for implementation I want to be certain that the data is transferred 1:1 into CAD. IT is reassuring to know that this case, 100 percent.

says Markus Schmid.

“Data transfer is easy and straightforward, so you can start working straight away with the captured measurement data. Also, the fact that you can measure everything at once doesn’t do any harm … :)

I think the camera and the camera's zoom option are sensational."

In upcoming projects, Metallbau Schmid already sees many different use cases of its new 3D Disto, from the installation of glass or metal cladding of large, outward facing staircases to staircase shape, step height and step depth. We wish them a lot of success with all upcoming projects using the 3D Disto.

The pre-installed structural components are positioned in a circular way and unfortunately, relatively large tolerances resulted in all of those leaning towards different directions; skewed to the left and right and tilting inwards or outwards. Therefore, every mounting required to be measured and modelled individually.

Summary:

The CompanyMarkus Schmid Metallbau Ziegelhütte 6 88147Achberg | Germany The ChallengeExact measurement of 54 skewed structural elements (embedded in a circle in concrete) from one position. Transfer of data to CAD. The SolutionHigh precision survey taken from one position only using the 3D Disto and with the aid of an adapter plate mounted on the respective installation part for measurement purposes. |

The Results

3D Disto product features

|