日本を代表する大手総合建設会社の大成建設株式会社は、本社の建築本部デジタルプロダクトセンターが中核となり、3D レーザースキャンおよび3Dデータ活用を推進している。2022 年9 月竣工のソニックシティホール棟大規模改修工事においては、らせん階段部分の形状を速く正確に把握するために、ライカジオシステムズのイメージングレーザースキャナー「Leica BLK360 G1」を使って3Dレーザースキャンを実施。複雑な曲面で構成される空間形状の高精度な把握をわずか「2 人で半日」で完了して、施工図精度の向上、工事着工時期の前倒しなど、大きな成果をあげた。今後は、作業現場の生産性向上効果をさらに拡大するため、3Dレーザースキャン業務ができる人材を支店レベルで育成するなど、3Dデータ活用拠点の全国展開を計画中である。

改修工事は「現況形状の正確な把握」から始まる

JR 大宮駅から徒歩3 分。ソニックシティは、ホール棟、オフィス棟、ホテル棟の3つの部分で構成される総合コンベンション施設である。1988 年の竣工時は、オフィス棟が埼玉県で最も高層なビルとして話題を集めた。

築30 年以上を経て、ホール棟は、基幹系設備機器の更新と、安全性をより向上させるための天井構造の改修が必要になり、2021 年から2022 年にかけて営業を休止して、大規模な改修工事を行うことになった。

ソニックシティホール棟大規模改修工事は、電気、空調、衛生、機械、外壁など、合計12 社の専門会社が請け負ったが、建築関係の内部改修を担当したのが大成建設である。

「大ホールの天井・客席、小ホールの天井・客席の改修に加えて、ホール棟を貫くらせん階段に、手すりと間接照明を追加設置することになりました。新築なら図面どおりに作れますが、現況の壁や内周手すりを維持したまま、同じ見栄えの外周手すりを取り付けるためには、まず現況の形状をできるだけ正確に把握することが不可欠です」と、大成建設株式会社 関東支店 ソニックシティホール棟大規模改修工事作業所(以下、作業所) 課長の和田利之氏は説明する。

このらせん階段は、楕円を少しずつ崩していくようなデザインであり、各階の踊り場も少しずつ形が異なっているなど複雑な形状をしている。図面はあるが、30 年以上前ともなれば2DCAD さえあまり普及していない時代だ。1 カ所測っただけで、実物と整合していないことがわかった。そのため、不規則に湾曲した階段壁に合わせて手すりや間接照明を作るためには、現況計測が不可欠だと判断された。

2022 年1 月末、作業所は、大成建設本社の建築本部デジタルプロダクトセンターに、現況計測を社内依頼した。デジタルプロダクトセンターは現場を下見してすぐに、最新機器を使った3Dレーザースキャンを決断。ライカジオシステムズのイメージングレーザースキャナー「Leica BLK360 G1」( 以下、BLK360)を使った計測を、2 月初頭に実施した。

1988年の竣工時に、一般社団法人日本建設業連合会が国内の優秀な建築作品を表彰する「BCS賞」を受賞したソニックシティ。 ホール棟には、2500人収容できる大ホールのほか、小ホール、国際会議室がある。

作業が速くて品質の高い成果物を得られるのが

3Dレーザースキャン

「図面と現物が整合しない案件は数多くあります。こうした改修工事は、まず現況調査に多くの時間と労力をとられ、確実な施工計画を立てるタイミングが遅くなるという問題を抱えています」と、大成建設株式会社 建築本部デジタルプロダクトセンター 設備・リニューアルBIM室 課長の長沼大輔氏は語る。

従来のように、トータルステーション、巻き尺、レーザー距離計を使った計測では、人手も時間もかかりすぎる。しかも、天井の計測があれば、足場や安全設備の設置と撤去が必要になり、高所作業の危険も伴う。

こうした課題を克服するため、デジタルプロダクトセンターは早くから3Dレーザースキャンに注目してきた。

「3Dレーザースキャンは速い。また、トータルステーションではXYZ 軸の座標点の数値だけが得られますが、3Dレーザースキャンは点群データと360 度の球面カラー画像という品質の高い成果物が得られて、後作業も格段に効率がいい」と長沼氏。3Dレーザースキャンで得られるデータは情報量が多いため、BIM/CIMソフトウェアへとデータ連携させ、建設DXを加速する効果まで大いに期待できるという意味でも、品質が高いのである。

こうした狙いのもとでBLK360 を導入したのは、2019 年4 月のことだ。軽い、速い、タブレットPC連携、ソフトウェアが良い、しかも価格がリーズナブルであると、BLK360 ならではの特長を高く評価した。

「都市部の既存建築物は交通の便の良い所に立地していますから、現場には電車で行くことが圧倒的に多く、持ち運びやすいという特長を重視しました。また、コンパクトで軽量であれば、機器がたくさん置いてある手狭な小部屋や天井裏でもどんどん計測できます」と、デジタルプロダクトセンター 設備・リニューアルBIM室 課長代理の榊友幸氏は言う。さらに、「『速い』という評価には、1スキャン約3 分というこれまでにない計測スピードと、トータルの計測日数を圧縮できる、たとえば3 日かかる作業を3 時間にできるという速さと、2つの要素が含まれます」と語る。

タブレットPCと連携できるのもBLK360 の特長だ。2019 年の検討当時、タブレットPCで制御できる3Dスキャナーはライカジオシステムズ製品だけだったという。

「『1スキャン約3 分』というのは、点群データを取得するだけでなく、iPad Pro へのストリーミングが完了するまでの時間です。この速さ、手軽さのおかげで、iPad Pro の画面を計測現場で見て確認しながら作業を進めることがあたりまえになりました」と、デジタルプロダクトセンター 設備・リニューアルBIM室主任の鈴木裕司氏。帰社してから、柱の陰がうまくとれていなかったことに気づくなどの心配がなくなったのである。

ソフトウェアも充実している。たとえば点群データ同士を合成する精度が高いため、後処理の時間が短縮できる。メニュー表示も日本語化されていて親しみやすい。

さらに大きなポイントは、ライカジオシステムズ1 社のソフトウェアだけで、他社の点群専用ソフトウェアを介さずに、データをCADやBIM/CIMソフトウェアへ取り込めることだ。「ハードもソフトも含めて1 社で完結できれば、データ連携がシンプルになり、サポート対応も安心です」と榊氏は指摘する。

さらに長沼氏は、「Autodesk とLeica Geosystems の本社同士は様々なプロジェクトで技術連携や業務提携をして協業体制を強化しています。そういうところも、将来の確実なデータ連携につながると評価しています」と付け加えた。

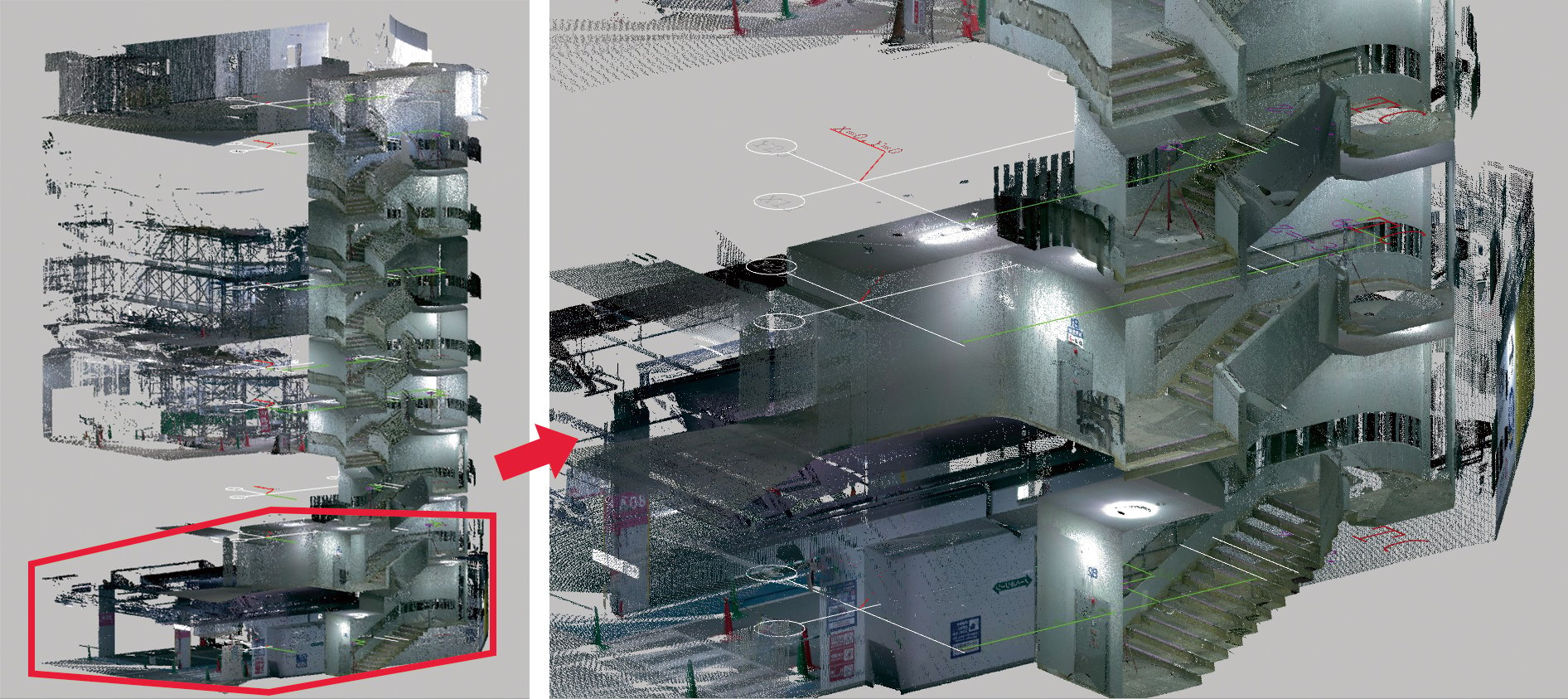

点群データとパノラマ画像を合成して、8階層あるらせん階段の全体形状を再現した。点群データの管理ソフトウェア 「Leica TruView」で表示

らせん階段計測で威力を発揮したBLK360 の倒立計測

ソニックシティホール棟のらせん階段は、地下2 階から大ホール最上階までの合計8 階層分が吹き抜けでつながっている。階段や壁の寸法採取というよりも、面積約50 ㎡の高い柱状の空間全体の形状把握をする必要があった。

計測メンバーは、階段踊り場の基準墨にターゲットを設置し、BLK360 で点群データを取得した。スキャナーを設置した機械点は8 階層で合計34 点。現地作業は「2 人で半日」で完了した。

BLK360 は、らせん階段内周の計測でも威力を発揮した。

この部分は内周手すりが三角形を描いて上下に連なっており、トータルステーションだと、三角形の鋭角のところが陰になって計測しにくい。ところが、吊り下げ用金具(クランプ)でBLK360 を手すりから吊るして倒立計測をしたところ、一度のスキャンで2 フロア分の点群データの取得ができて、非常に効率がよかった。

「この倒立計測機能はとても気に入っていて、他の現場でもよく利用します。たとえば、建物の外壁と地面までの境界を正確に3D把握したいとき、BLK360 を吊るして倒立計測するとうまくいきます」と榊氏は語った。

らせん階段の内周部は、手すりからBLK360を金具(クランプ)で吊るして、倒立計測を実施。三角形の鋭角部分で 陰になりやすいところも、きちんと点群データ取得できた。

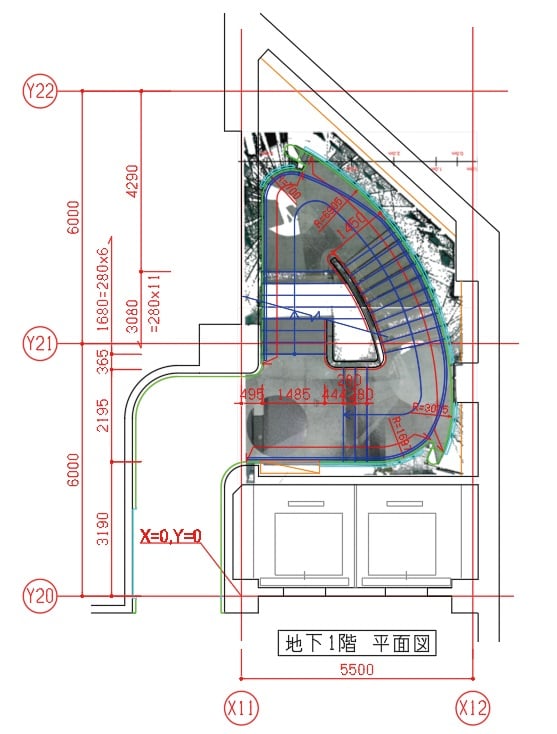

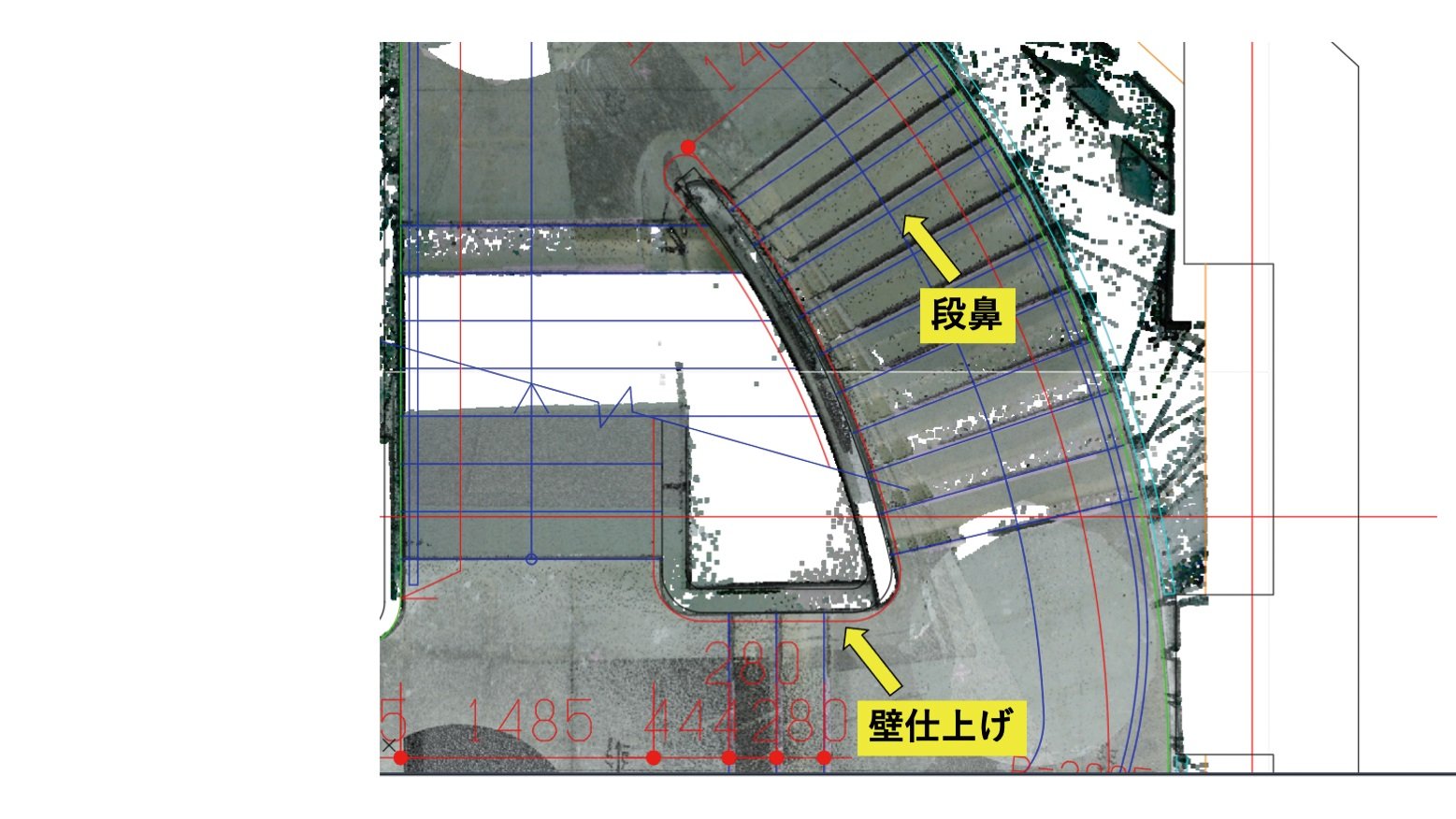

こうして取得し、合成した点群データはさまざまな活用が可能だが、今回は、オルソ画像に変換したうえで、座標を付与したり、既存図面と重ね合わせを行った。

オルソ画像は空中写真の後処理でよく用いられる技術だ。空中写真には、真上から撮影している部分と斜め角度から撮影している部分が必ずあり、斜め部分は寸法や位置が微妙に延びてズレが生じる。オルソ変換(正射変換)をすることで像の位置ズレがなくなり、地図と同じように、すべての部分が真上から見た正しい大きさと位置を表示する画像となる。

点群データもオルソ画像に変換することで、正しい大きさと位置を示す現況画像を得られる。これを既存図面と重ね合わせれば、図面との不整合箇所を誰でもひと目でわかる形で正確に表示できるのだ。

「3Dレーザースキャンで点群データさえ取れば、成果物の品質が上がって万事解決、というものではありません。計測した情報を関係者で共有するために、オルソ画像を簡単に生成できるかどうかが大きな意味を持っているのです」と長沼氏は強調する。点群データも図面と重ねて比較できるが、点群データはそのままでは大容量であり、ハイスペックなPCでないと扱いにくい。オルソ画像にすればデータ量が圧縮されるため、取り扱いが楽になる。

和田氏は、「点群データをオルソ画像に変換して社内納品してもらったので、作業所の関係者全員がそれぞれの立場で活用しました。

閲覧しながら打ち合わせしたり、オルソ画像をなぞる形で2DCADデータを作ったり、手すりや間接照明を作る協力業者と打ち合わせする資料もすぐに作れました」と語る。施工図も通常よりも早く作成でき、工事の開始時期も前倒しにできたのである。

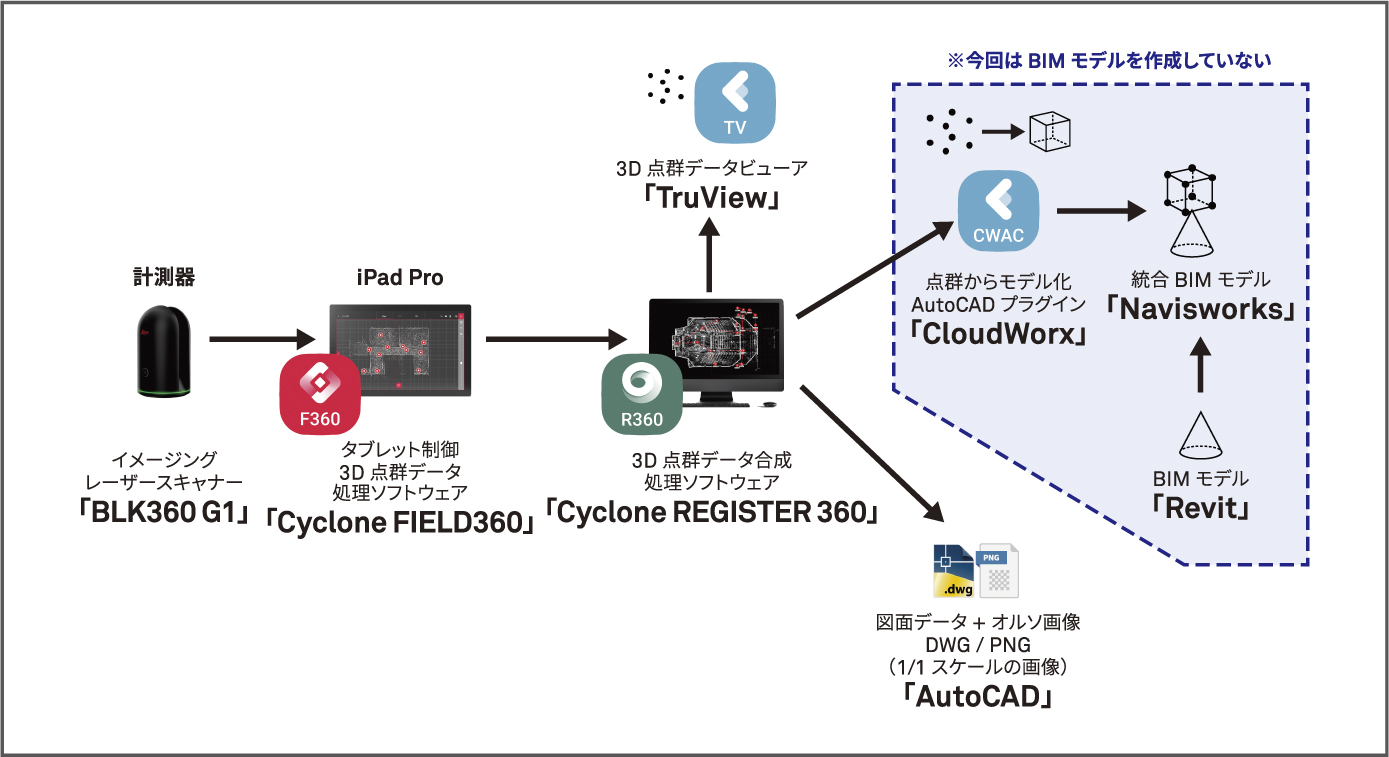

計測した点群データは、スタンダードなワークフローとしては、点群データ合成処理ソフトウェア「Cyclone REGISTER 360」からCADプラグイン「Leica CloudWorx」に取り込み、2D図面や3Dモデルなど多様なデータを生成して、CADやBIM/CIMソフトウェアで活用していく。ただし今回は、BIMモデルを作る必要がなかったため、Cyclone REGISTER 360 によるオルソ画像生成のみで、Leica CloudWorx は使わなかった。また、点群データを閲覧したりリアルタイムに共有するために、デジタルプロダクトセンターでは、点群データ共有ソフトウェアの「Leica TruView」を利用している。

このように、作業はすべてライカジオシステムズのハードとソフトだけで完結するため、操作は共通でわかりやすく、データのエクスポート/ インポートもスムーズである。

Cyclone REGISTER 360で、点群データをオルソ画像に変換。座標情報をつけたうえで、AutoCADで平面図を作成した

今回のプロジェクトでは、通常スペックのPCでも取り扱えるまでオルソ画像の容量を圧縮。既存図面と重ねて

不整合部分を明確にしたうえで、情報を伝達するPowerPoint書類なども各自の創意工夫で自在に作成した

わずか「2 人で半日」の作業でなめらかな曲面を高精度に把握

ソニックシティホール棟大規模改修工事は、2022 年9 月竣工する。らせん階段部分の工事は、第1プロセスである「現況把握」に、BLK360 による3Dレーザースキャンを採用したことで、全体の流れが大きく変わった。

まず、現況計測の時間が大幅に短縮できた。

「トータルステーションとは大違い。圧倒的なスピード、圧倒的な差です」と和田氏。「トータルステーションの場合、曲面の精度を上げるには測定点の数をひたすら増やしていくことになります。あの階段の壁面の『複雑ななめらかさ』を把握するには、1 週間はかかったのではないでしょうか。3Dレーザースキャンなら一瞬、いや3 分間でできてしまいました」とにこやかに語る。

しかも精度が高い。壁の曲面を正確に把握できた。

作業所では、従来はトータルステーション計測の数値を入力してCAD図面を描いていたが、規則性のない複雑な曲線や形が変化していく楕円形などは、精度を上げるのがむずかしかった。今回は、オルソ画像の点群を利用することで施工図の精度が上がり、手すりと間接照明の取り付け工事の精度も高めることができた。

また、近年では発注者(施主)や設計会社も、建設DX に対して積極的に取り組んでいる。ソニックシティホール棟の工事成績評定では、発注者である埼玉県が、3Dレーザースキャン計測から施工図作成までの流れ、随所の創意工夫を興味深く聞き取り、高く評価してくれた。

既存建築物の現況計測は「スピード」が重要

デジタルプロダクトセンターがBLK360 を導入して3 年経った。初年度は試用が多かったが、最近では使用頻度が高まっており、累積スキャン数は4,000 スキャンに達した。

「慣れてくると、1 日に機械点70 点とかをあたりまえにとっています。ほとんど『秒刻み』作業です」と長沼氏は言う。すごいスピードだ。

内容は、たとえば、ホールなどの吊り天井に鉄骨を仕込んで耐震性を強化する特定天井工事である。音響効果などを計算して設計された曲面は正確に維持しなければならない。そこで、吊り天井のままで、現状の曲面を高精度に計測する作業が必要になる。

伝統建築、特に神社仏閣は、現況と図面が不整合である確率が高い。しかも、実物に触れてはいけないため、3Dレーザースキャンが活躍する。

建物内部だけでなく、外構計測や土工計画で用いることもある。

敷地内にスロープを作るため、搬入すべき土の量と、搬出しなければならない土の量を算出する調査でもBLK360 は役に立った。道路が狭かったり急斜面だったりして、建築現場につながる道路補強や拡幅の計画を立てるときにも、周辺道路を3Dレーザースキャンすると効果的だ。

工事現場で一緒になった専門業者がたまたま、BLK360 とその上位機種のLeica RTC360 を持っていたため、協力して計測したこともある。ターゲットを共有したりしながら、建物の中、屋上、外構を手分けすることで、広範囲を短時間で計測できた。

これほどに「スピード」にこだわるのは、効率や生産性のためだけではない。

「時間短縮はとても重要な要件です。お客様が居ながらの作業であったり、同時進行している工事を中断させないなど、既存建築物の現況計測は集中してすばやく現場作業を完了させなければならないことが多いからです」と長沼氏は語る。ある駅舎を計測したときも、人の流れを邪魔することなく、短時間で正確な計測をするために、BLK360 を活用した。

3Dレーザースキャン効果を全国作業所の生産性向上へ拡大

使えば使うほど3Dレーザースキャンの威力を実感するデジタルプロダクトセンターでは、現在保有しているBLK360 以外の製品も導入し、組み合わせて利用することで、さらに革新的な効果を生み出したいと考えている。

いま導入を検討している製品の筆頭が、BLK360 シリーズで新発売された「Leica BLK360 G2」だ。

「BLK360 G1 が、小さくなって、速くなって、精度が上がった。これは使いたいですよ」と榊氏は力を込めて語る。

BLK360 の上位機種であるRTC360 にも注目している。スキャン密度が高いうえに、最大測定可能距離が、BLK360 の2 倍以上の130 mもあるからだ。「建築デザイナーが設計した意匠建築や伝統建築などは、RTC360 で計測したい」と榊氏は言う。

移動体ハンディレーザースキャナー「Leica BLK2GO」はテスト中だ。手で持って移動しながら計測できるので、「現場を止めない計測」をより強化できるのではないかと期待している。

ソフトウェアは、オールインワンの点群活用ソリューション「Leica Cyclone 3DR」に熱い視線を注いでいる。今回、作業所ではオルソ画像をなぞって2DCADデータを作ったが、Leica Cyclone 3DR ではより効率的な手段を利用できそうだ。

「3Dレーザースキャンがどういうものか、知識としては知っていましたが、実際に使ってみたら想像以上に効果が大きくて、今回のプロジェクトは本当に有意義でした。この認識を社員みんなに広めて、『既存建物の改修なら、最初のプロセスは3Dレーザースキャン』がスタンダードとなるようにしたい」と和田氏は意欲的に語る。

デジタルプロダクトセンターとしても、3Dレーザースキャンができるキーマンを支店・現場で育成するなど、様々な計画を立てて取り組みを始めたところだ。

「社内はもちろん、すでにライカ製品を持っている専門業者や協力会社の方々も、力を結集できるような体制を作りたい。

大事なことは、全国の作業所で生産性が大きく向上するような展開をすることです」と長沼氏は語る。

重さわずか1 kg のコンパクトなBLK360 は、スーパーゼネコンの業務プロセスを変革し、企業の壁を越えた協業まで促進するような、大きな可能性を内に秘めているのである。

記載されている製品名・ロゴなどは各社の商標または登録商標です。

BLK360

BLK360

BLK2GO

BLK2GO

BLK2GO PULSE

BLK2GO PULSE

BLK ARC

BLK ARC

BLK2FLY

BLK2FLY

BLK3D

BLK3D

BLK247

BLK247

Software

Software

Accessories

Accessories