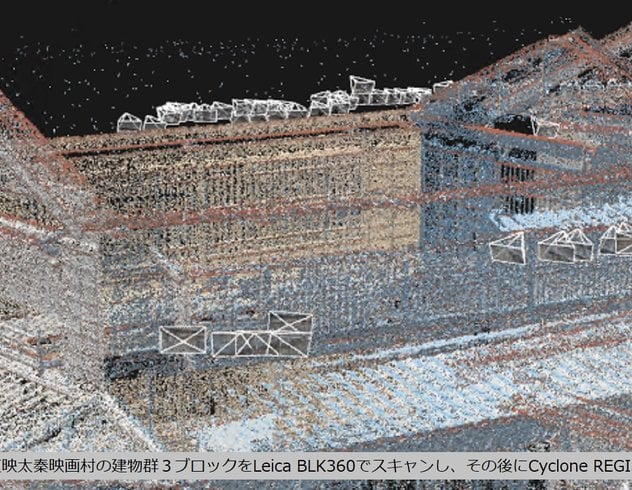

Faithful Land Registration Survey, based in Osaka and operating throughout the Kansai region, is a firm of land surveyors specializing in investigating and surveying the locations and shapes of land and buildings. These professionals handle registration procedures at legal affairs bureaus. Their work ensures the accurate reflection of real estate conditions in registration records, contributing to the security of real estate transactions, clarifying corporate and individual property ownership, and avoiding disputes related to inheritance and other matters. In November 2019, Faithful Land Registration Survey introduced Leica Geosystems' imaging laser scanner, the Leica BLK360to accelerate and streamline their on-site survey operations, achieving success in speeding up their processes. Their next goal is to further explore and apply the use of 3D data.

Using a 3D laser scanner for speeding up on-site operations

"Takashi Nakata, the land surveyor operating Faithful Land Registration Survey, explains, 'For land, we conduct definitive boundary surveys and investigate land classifications (zoning), submitting the survey results for registration at legal affairs bureaus. For buildings, we survey types, structures, and floor areas, also submitting these details for registration.'"

Faithful Land Registration Survey's clients primarily include real estate companies involved in custom-built homes and speculative construction, as well as construction companies and architectural firms. They receive direct requests for land surveys and registration from both businesses and individuals.

"Nakata continues, 'Surveying and appraising the invisible "boundaries" requires meticulous and sincere efforts. Expertise in the industry, including the ability to explain clearly during meetings with adjacent property owners, is indispensable. However, achieving the final result of "registration" often emphasizes speed and cost-efficiency over service details. Therefore, I believe that meeting customer demands for speed and cost requires ongoing corporate efforts to adopt new methods and the latest technology.'"

"We aim to enhance our operations by speeding up tasks and reducing unnecessary processes to improve our handling of projects and customer relations. That's why we have focused on utilizing the 3D laser scanner."

BLK360's Mobility Creates Advantages

Mr. Nakata, who was exploring methods for business innovation, had the opportunity to use a 3D laser scanner in 2019.

"I felt that the significance of reliably reducing on-site work time was substantial, despite the additional computer work after the survey, such as point cloud synthesis, unnecessary point removal, and change point extraction. Choosing a compact device that can complete measurements alone could significantly change how field work is done," said Mr. Nakata. After considering multiple products, he settled on the BLK360.

The deciding factors were performance, mobility, and price. "I evaluated products from other companies and other models from Leica Geosystems, but I liked the BLK360 for its compact size and high performance. Its vertical orientation makes it convenient for measuring in tight spaces," Mr. Nakata explained.

Compared to other products he considered simultaneously, the competitors were about four times heavier than the BLK360 and approximately 2.2 times more expensive. "Being lightweight and highly mobile means it can be used easily in everyday scenarios. From an investment perspective, this was a significant advantage," Mr. Nakata concluded.

Effortlessly and Stress-Free Measurements in Challenging and Obstructed Sites

In November 2019, shortly after introducing the BLK360, Mr. Nakata immediately experienced various benefits brought by its exceptional mobility.

Traditionally, traverse surveys using total stations required a team of two: one person would move a prism to measurement points while the other would measure with the total station. This process involved moving the prism to each subsequent point for measurement, often requiring creative solutions like increasing measurement points or circumventing obstacles like trees or walls. This method, known as traverse surveying, was limited by line of sight between points, making it challenging in obstructed areas.

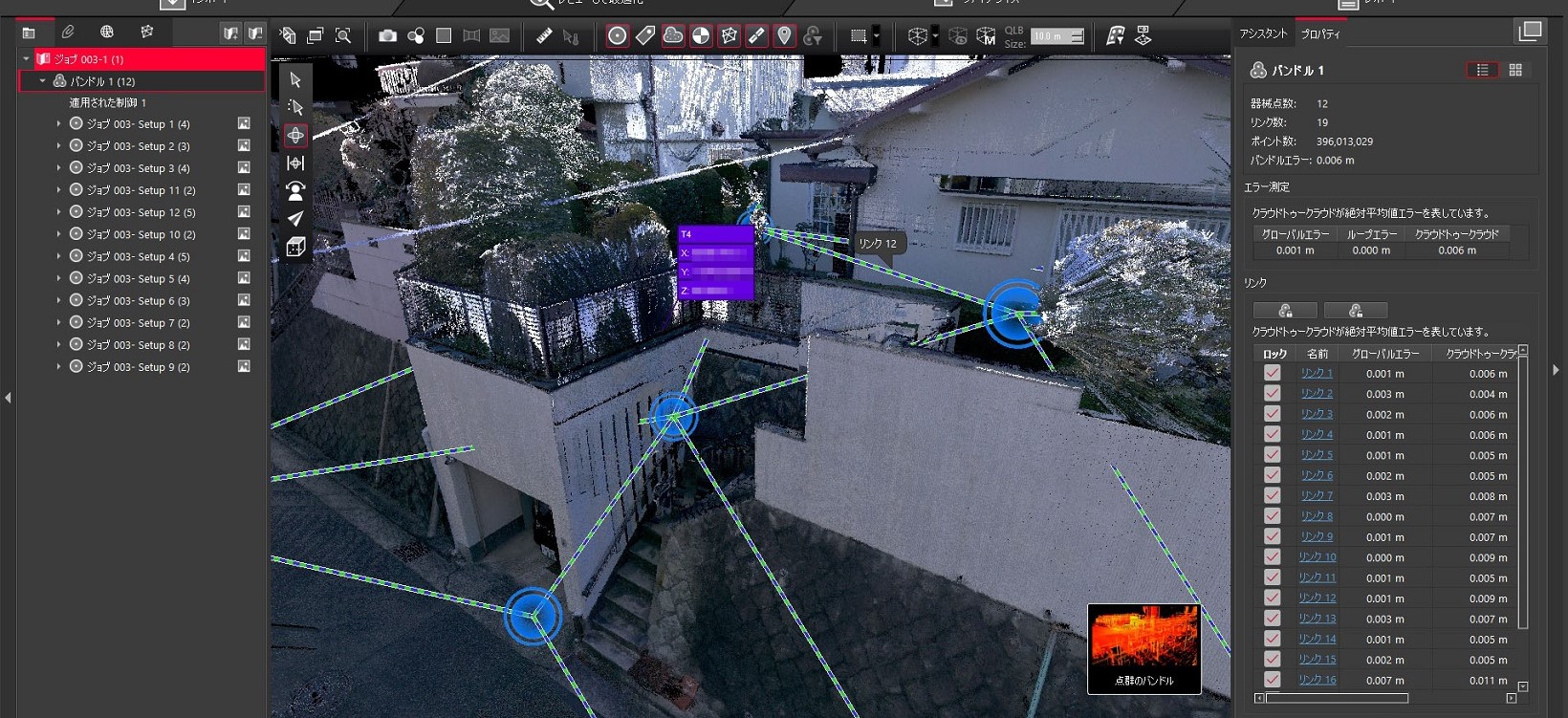

"Surveying sites with poor visibility, such as navigating through high fences and stairs to reach doorways, was very stressful and difficult with a total station. However, with the BLK360, even if the line of sight between instrument points is obstructed, there's no need to worry. By setting up BLK360 in multiple locations across the survey area and capturing point clouds, it's possible to synthesize points based on visible landmarks like utility poles that are visible on the sides where walls may not exist," Mr. Nakata emphasized. "Even in sites with poor visibility and high stress, the BLK360 allows us to obtain measurement data with minimal scanning sessions, significantly reducing on-site work time—a major advantage."

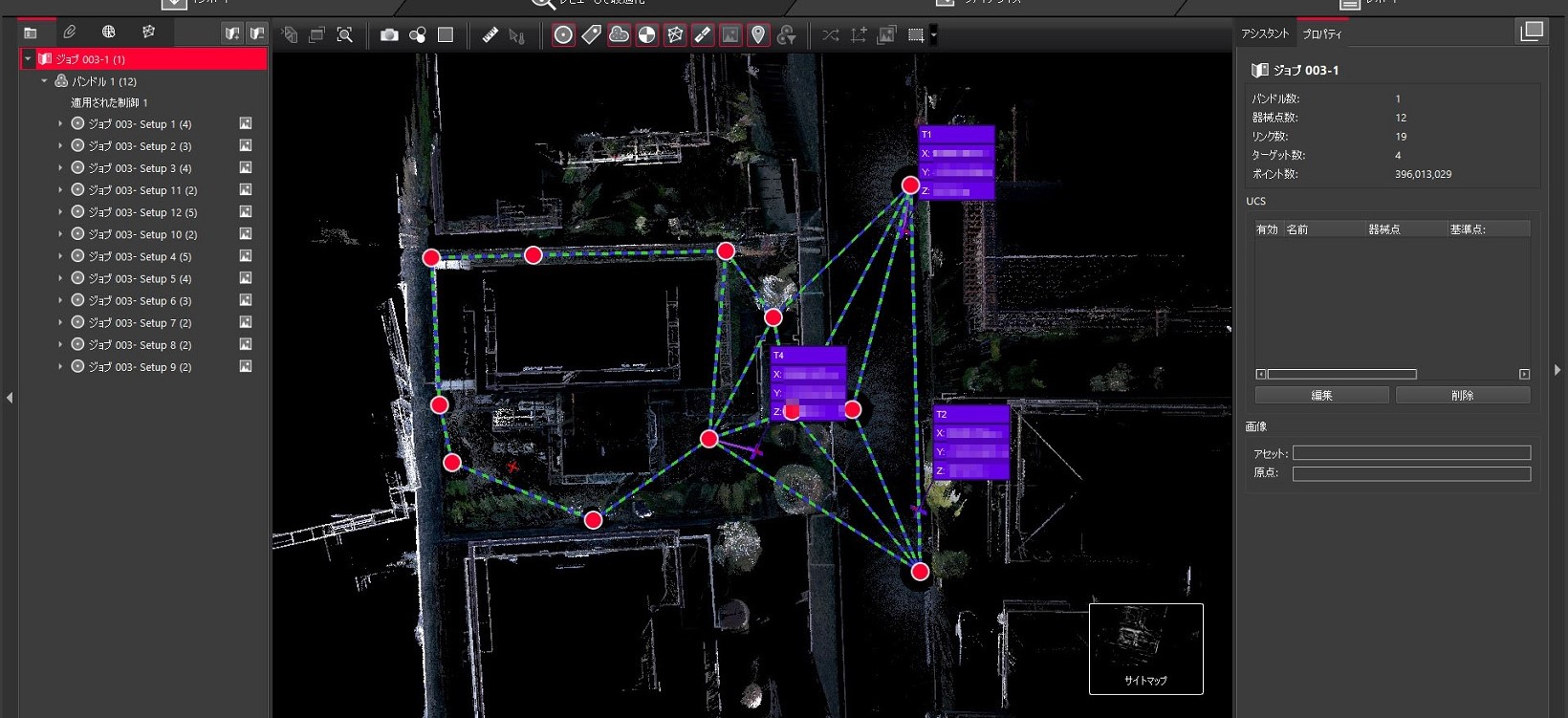

In sites with poor visibility where total stations struggle, the BLK360 can measure smoothly. The blue circles indicate instrument points where the BLK360 was placed. On the right side, behind the white fence, the visibility between instrument points was obstructed, causing the dashed line link to break. However, point cloud synthesis was successfully achieved without any issues.

An overhead image of the site shown in the previous figure. There are 12 survey points established, with only 3 serving as markers for synthesizing global geodetic coordinates. Each point took approximately 5 minutes to scan, resulting in the completion of on-site work in just over an hour. Moreover, the placement of survey points caused minimal concern and stress, allowing for seamless completion of the task.

Unlike photogrammetry in the same realm of three-dimensional surveys, the 3D laser scanner can operate during dim early mornings or evenings, offering flexibility in scheduling on-site operations.

"When I was commissioned for a job and heard 'the building will be demolished tomorrow,' I hurriedly brought the BLK360 to the site. It was already evening, but I managed to scan the data alone without any issues," Mr. Nakata said. Subsequently, during a meeting involving neighboring property owners, discussions arose such as "the demolished building was precisely at the midpoint between your wall and ours," prompting clarifications like "does your roof extend beyond the boundary?" Although the building was gone, Mr. Nakata prevented potential disputes by immediately presenting the BLK360's 3D images to confirm the precise boundary locations to both parties.

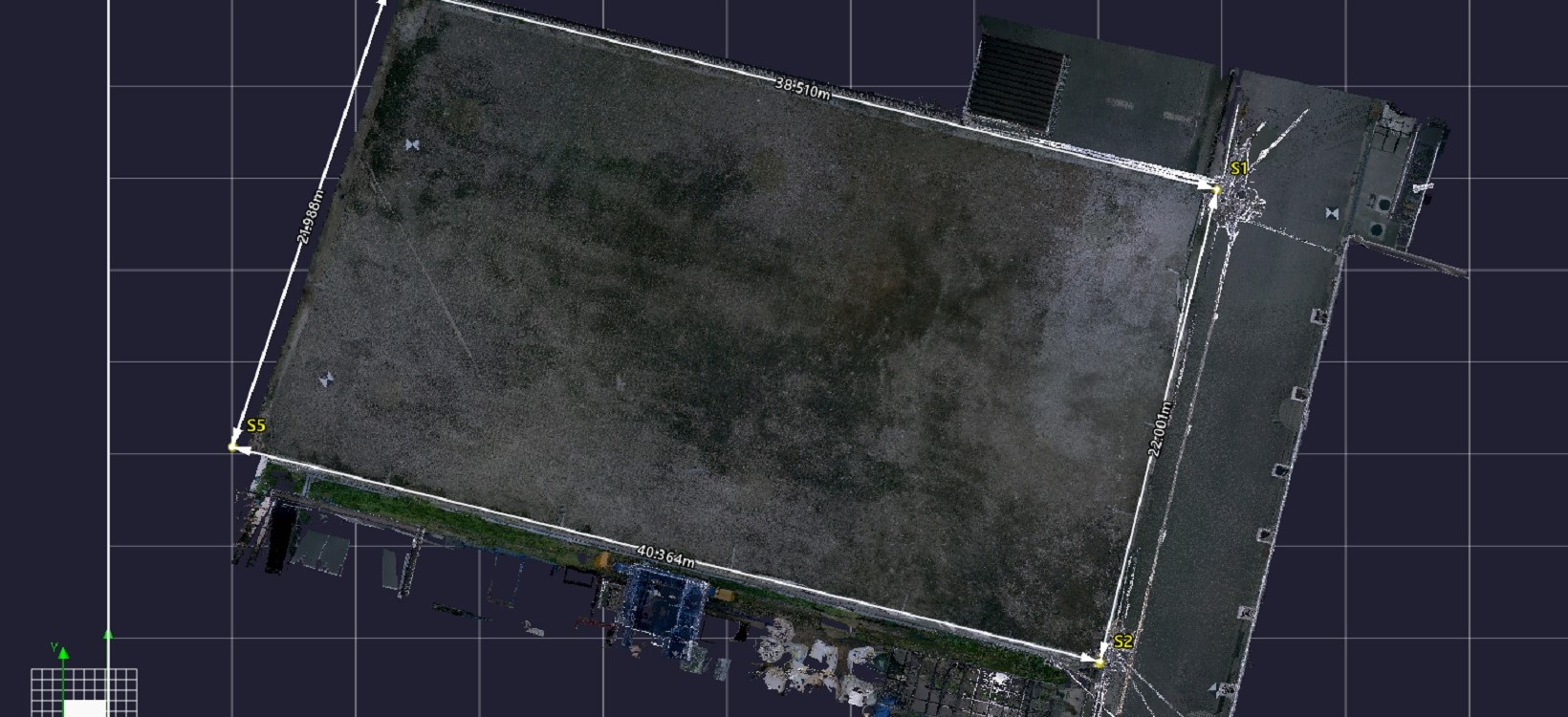

When commissioned for the job, Mr. Nakata hurriedly conducted measurements alone upon being told, "The building will be demolished tomorrow." During a subsequent site visit, concerns were raised about whether the roof of the square-shaped building in the lower center was encroaching beyond the property line, but it was immediately clear that it wasn't.

Furthermore, during provisional surveys, the convenience of the BLK360 was particularly evident.

Typically, in conventional surveys, surveyors install traverse points near the site from the nearest public reference point and associate these traverse points with global geodetic coordinates before commencing work for the day. This initial task of "installing public reference points" to convert site data into global geodetic coordinates requires about three hours with two people. It's an important but labor-intensive task that must be done at the outset.

However, with the BLK360, provisional surveys can commence without installing public reference points. Contrary to the traditional method of associating global geodetic coordinates from public reference points to traverse points installed near the site, the BLK360 connects point cloud data from the site to the nearest public reference point for coordinate transformation. Of course, eventually, each boundary point is precisely surveyed with a total station after installing public reference points using the conventional method. Nevertheless, the ability to obtain site data associated with global geodetic coordinates even when conducting a current condition survey alone provides significant advantages.

Another significant contribution to reducing on-site work time is the elimination of the need for additional measurements. Previously, after measuring and assessing the boundary lines to deliver a plan view, there were often additional requests such as, "Now that we know the boundaries, please measure the levels (elevations, slopes)," or instructions to create a cross-section diagram at specified positions, followed suddenly by requests like, "Oh, we also need a cross-section diagram for this position."

In the past, each time this happened, they had to revisit the site to redo the measurements. Alternatively, during on-site work, they would sometimes make judgments like, "Even though it wasn't requested, it might be good to measure this area as well," and somehow manage to cope. However, revisiting the site or taking "extra measurements just in case" were not only unnecessary but also increased wasted effort and downtime.

"With the BLK360, we've solved this issue of 'redoing on-site work.' With 3D data available, we can quickly respond to additional requests for level measurements, cross-sections, or any other tasks through computer processing. Moreover, if suddenly asked, 'How high are the windows of the neighboring house?' I can immediately show a 3D image and provide an answer," Mr. Nakata said with a smile.

Achieving Approximately 30% Reduction in Work Hours Overall

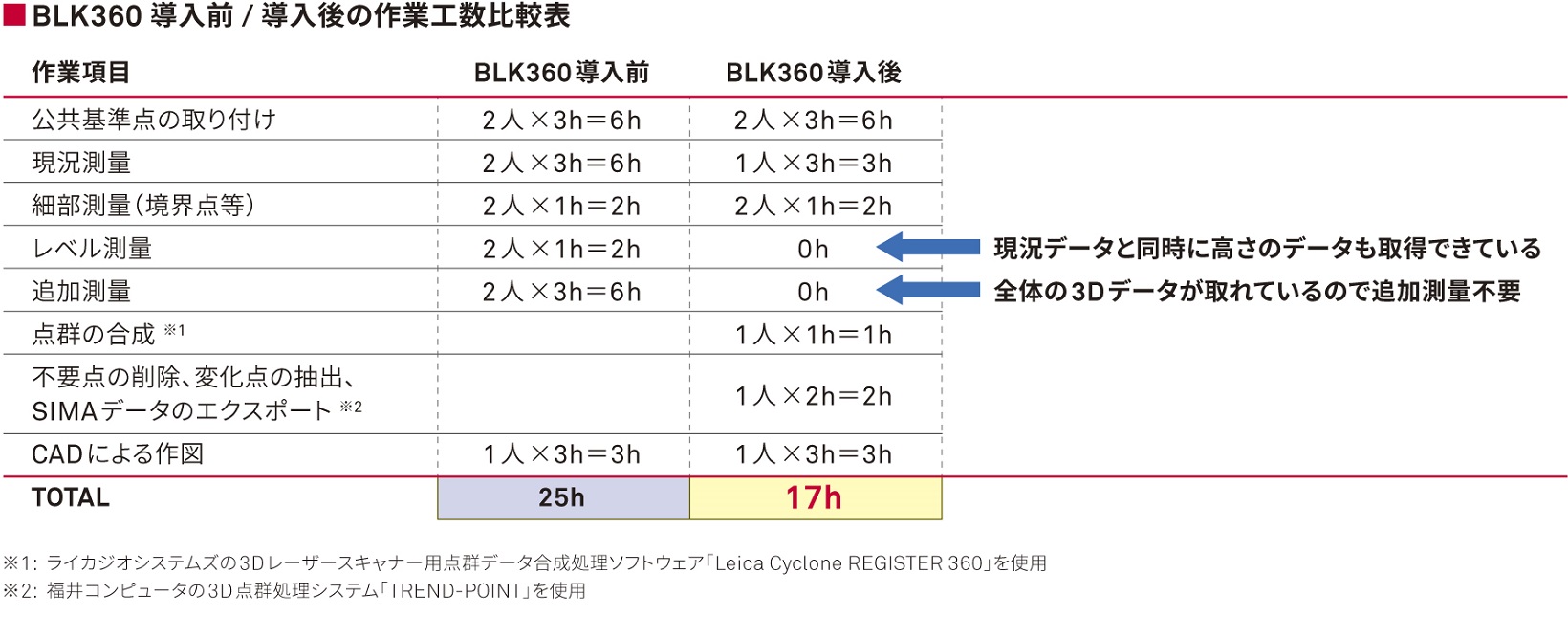

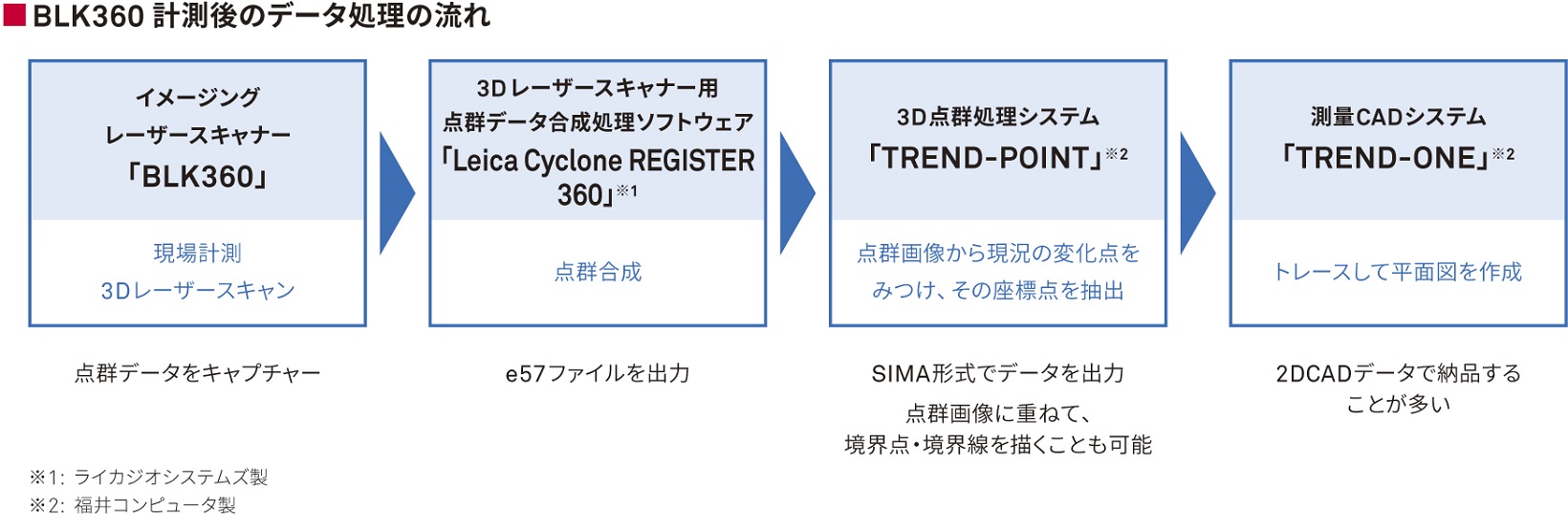

As initially expected, the BLK360 has delivered significant results in reducing on-site work time. "I've prepared a table using an example of a single-family home of about 100 square meters. For an 'as-built survey,' which previously took two people around three hours using a total station, now with the BLK360, I completed it alone in three hours. This reduced the workload from 6 person-hours to 3 person-hours," explained Mr. Nakata (refer to the 'Comparison Table of Work Hours Before and After BLK360 Introduction').

As seen in this table, even after the introduction of the BLK360, tasks requiring accuracy such as installing public reference points and measuring boundary markers continue to be conducted using a two-person team with a total station as before. Additionally, office tasks following the survey, such as "point cloud integration" and "point cloud editing including removal of unnecessary points," were added after its introduction.

When we consider these additions and subtractions, it becomes evident that tasks that previously required "25 person-hours" have been reduced to "17 person-hours," a reduction of approximately 30%.

"It's challenging to complete all surveys solely with the BLK360, but for preliminary surveys where public reference points are not set, the time-saving effect is more pronounced. There have been instances where a task that would take two people 4 hours was completed by one person in 2 hours, a reduction of one-quarter of the workload. Previously, even for preliminary surveys, we had to go out with two people carrying the total station," Mr. Nakata elaborates.

Moreover, beyond mere reduction in workload, the significance lies in the ability for one person to conduct the current state survey with the BLK360 while the other can go to the municipal office for document research concurrently, as well as an increase in tasks that can be completed by a single person. This has significantly increased the flexibility in our operations.

Looking ahead, the unique strengths of Faithful Surveying, such as providing 3D images and analyzing 3D data, are expected to lead to differentiation from other firms and expand business opportunities.

Already, there has been positive feedback from customers and stakeholders for producing videos explaining point cloud data and attaching 3D images showing boundary points and lines within drawings. Additionally, customers have shown interest in utilizing 3D data for designing spec-built homes, as simply having Windows allows them to operate measurements using the viewer. With increasing societal recognition of the utility of 3D data, further attention is expected to follow.

Watch the video: 3D image data showing boundary points and lines highlighted within point cloud data acquired using BLK360 (by Faithful Surveying).

A 3D video created by Faithful Surveying highlighting boundary points and lines within the point cloud data.

In addition, there is potential to expand job opportunities by combining UAV surveys with BLK360.

UAV surveys can measure large areas quickly. However, there are strict regulations such as not being able to fly near highways and the requirement for prior notification to authorities including the police.

With BLK360, there are essentially no places where measurement cannot be performed. It is safe to conduct surveys without the risk of crashes, and data acquisition is possible even at night due to it being laser-based rather than photo-based. It can operate in light rain as well.

While conducting UAV surveys over large areas, Nakata is considering new initiatives such as using BLK360 for surveys in places where drones cannot fly, such as near highways and densely populated urban areas with buildings, and integrating the 3D data from both approaches.

Great Expectations for Future Real Estate Registration in 3D

Mr. Nakata aims to expand beyond the framework of land and house surveyor duties and explore the potential applications of 3D scan data.

One such initiative involves submitting a proposal for a demonstration experiment to archive important cultural properties like Notre-Dame Cathedral and Shuri Castle, amid recent fires. Since drones cannot fly directly above such cultural assets, BLK360 would be extensively utilized.

There is also high anticipation for the 3D conversion of real estate registration. Currently, flat diagrams are required for real estate registration, necessitating the conversion of richly acquired 3D data into less informative 2D data. "Current registration records provide only planar information and register the land area," Mr. Nakata explains. "However, even lands with the same area can vary significantly in value depending on whether they are flat or steep. If registration is 3D-converted and standardized with height information in global geodetic coordinates, it would increase the judgment criteria available simply by looking at the registry. I believe this would provide valuable information not only to real estate and design companies but also to local governments planning infrastructure development."

While transforming real estate registration into 3D faces barriers such as modifications to legal bureau systems and legislative changes, Mr. Nakata sees it as a worthwhile reform akin to the i-Construction initiatives in the civil construction industry—a vision that holds great promise.